Tristan Pulford, Principal Consultant at Finch Consulting, delves into the core elements of how to identify and manage potentially explosive substances, emphasising how employers can recognise and mitigate hazards associated with explosive substances and atmospheres, with a primary focus on safeguarding the health and safety of workers. You can catch up on part one at the bottom of this article.

Posted

31.01.2024

Written by

Hazardous Area Classification

Hazardous area zoning, also known as area classification, is a systematic approach used to identify and classify areas where the presence of potentially explosive atmospheres can occur. A potentially explosive atmosphere is any area where a fuel (a flammable dust, vapour or gas) can become airborne as part of the process or due to foreseeable failure of a process or equipment. The purpose of hazardous area zoning is to manage and mitigate the risks associated with the presence of flammable gases, vapours, liquids, or combustible dusts. This classification is crucial for the implementation of safety measures, equipment selection, and the development of safe working practices in environments where explosive atmospheres may be present.

Hazardous areas are divided into zones based on the frequency and duration of the presence of explosive atmospheres. The classification system is defined in international standards, and it provides a standardised way to communicate the level of risk associated with different areas within a facility. These zones are as follows:

| Dust Zone | Description |

| Zone 20 | A place in which an explosion atmosphere in the form of combustible dust in air is present continuously, or for long periods or frequently. |

| Zone 21

|

A place in which an explosive atmosphere in the form of combustible dust in air is likely to occur in normal operation occasionally. |

| Zone 22

|

A place in which an explosive atmosphere in the form of combustible dust in air is not likely to occur in normal operation but, if it does, will persist for a short period only. |

| Gas Zone | Description |

| Zone 0 | A place in which an explosion atmosphere in the form of combustible gas/vapour in air is present continuously, or for long periods or frequently. |

| Zone 1

|

A place in which an explosive atmosphere in the form of combustible gas/vapour in air is likely to occur in normal operation occasionally. |

| Zone 2

|

A place in which an explosive atmosphere in the form of combustible gas/vapour in air is not likely to occur in normal operation but, if it does, will persist for a short period only. |

| Zone 2NE | A place in which an explosive atmosphere in the form of combustible gas/vapour in air is not likely to occur in normal operation but, if it does, will persist for a short period only and will extend to negligible extent |

Where to expect hazardous areas?

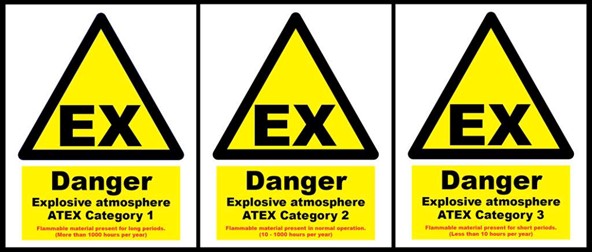

There is a duty on the employer to inform anyone working in a hazardous area of the hazards present, part of which is informing them that they are working in an area with hazardous areas. This is frequently implemented through training and localised signage on any entry point to the area which may look like this:

It is also essential to be able to identify likely release points, from which potentially hazardous areas can be generated, in the case of a new or changed process. At this point because of the differences between gas, vapour and dusts, we need to consider the release points differently.

Gas / Vapours

Whilst gases come in various forms many of the ones used in industry are colourless and as such a release may be hard to detect without specialist equipment. Typically, these systems have a few common release sources with associated hazardous areas:

- Process Vents;

- Pressure Relief;

- Flare Stacks;

- Flanges;

- Valve Stems; and

- Regulators.

Dusts

Hazardous area zones generated by dust tend to be easier to spot, as they are frequently visible. The dust must be airborne and as a rule of thumb, the concentrations required to be potentially explosive means you would not be able to see 1m through the dust cloud. Frequent areas where dust zones are present are:

- Hoppers;

- Filters and drop out bins;

- Internal pipework;

- Flexible Hoses; and

- Breathers.

One important aspect of dust is that if there are layers of dust over equipment or an area then this can become a zone. The best practice is to ensure housekeeping is in place so that there is never a layer of dust thicker than 2mm present, otherwise, zoning should be considered.

Liquids

Flammable liquids stored at pressure can also create a potentially explosive atmosphere, although the regulations and standards are a little vaguer. In general, the release points are the same as gas and vapours, however, they require the liquid to be at pressure, i.e., if a flammable liquid is being pumped across site. The hazard posed by pressurised systems of this nature is that in the event of a leak, there is the possibility of mist formation generating a potentially explosive atmosphere.